ECOLUBE 3D

Lubrication systemsSheet metal, wire and tube processingAutomotiveMould constructionSawingMedicalMilling, turningAviation

Top Functions

- Individual control of metering units

- Internal tool lubrication by injector & lateral external lubrication (combined system)

- Circular saw >Ø 500mm

- lateral external lubrication

- Internal tool lubrication by injector

Top functions

Technical data

- Micro lubricating filmConstant

- Number of nozzles1+2

- Delivery rate of lubricant per metering unit0 - 0,0155 ml / stroke

- Air flow rate per metering unit0-150 Nl / min

- Dimension WxHxD180 mm x 430-460 mm x 140 mm

Typical operating costs

- Lubricant cost / h0,16 CHF

- Air cost / h0,18 CHF

- Electricity cost / h0,00 CHF

- Total / h0,34 CHF

Basic equipment

- Reservoir size0,8 Litre

- Main control on / offElectric main control valve

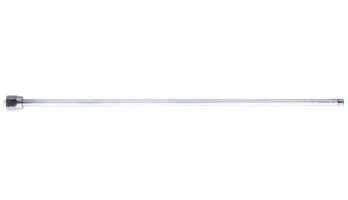

- Coaxial supply line2,1m

- Nozzle armmade of plastic 300mm + TimJet

Options

- Reservoir1,5 Litre

- Main control

- Pulsing metering unit

- Extra length coaxial supply line2,1 - 17,0m

- Nozzle armAll nozzle arms possible

- Rotary transmissionyes

Industry solutions

- Automotive industry

- Medical technology

- Aviation

- Mold making

production method

- Internal coolant supply IKZ

- CNC milling & turning

- Portal milling machines

- Large circular saw

- Sheet metal, wire and tube processing

- Sawing

Beschreibung

Drastic reductions in operating costs and huge increase in tool life. Maximum efficiency through minimized processing times. This is what the minimal lubrication systems from UNILUBE stand for. Unilube lubrication systems only apply as much lubricant as is required for the process. A highly economical concept of quasi-dry machining.