PULSLUBE

Lubrication systemsDosingAssembly, automationAutomotiveMetalworking in generalPlant construction, process technologySurface technology, thin-film process

Top Functions

- Dosing accurate to the microgram

- Cutting & non-cutting automation systems

- Rotary indexing tables

- lateral external lubrication

Technical data

- Micro lubricating filmpulsating

- Number of nozzles1

- Delivery rate of lubricant per metering unit0.004 - 0.0375 ml / stroke

- Air flow rate per metering unit0-2 Nl/pulse

- Dimension WxHxD140 mm x 240 mm x 120 mm

Typical operating costs

- Lubricant cost / h0,26 CHF

- Air cost / h0,03 CHF

- Electricity cost / h0,00 CHF

- Total / h0,29 CHF

Basic equipment

- Reservoir size0,3 Litre

- Main control on / off

- Pulsing metering unitelectric pump control valve

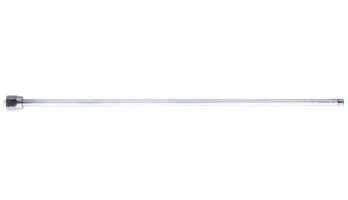

- Coaxial supply line

- Nozzle arm300 mm made of inox

Options

- Reservoir

- Main control

- Pulsing metering unit

- Extra length coaxial supply line

- Nozzle arm

- Rotary transmission

Industry solutions

- Plant construction

- Process technology

- Automotive

- Plant construction, process technology

- Metalworking in general

production method

- Automation systems & rotary indexing table

- Surface technology, thin-film processes

- Surface technology, thin-film processes

- Dosing

- Assembly, automation

Beschreibung

Drastic reductions in operating costs and huge increase in tool life. Maximum efficiency through minimized processing times. This is what the minimal lubrication systems from UNILUBE stand for. Unilube lubrication systems only apply as much lubricant as is required for the process. A highly economical concept of quasi-dry machining.