- Blog

- Product news

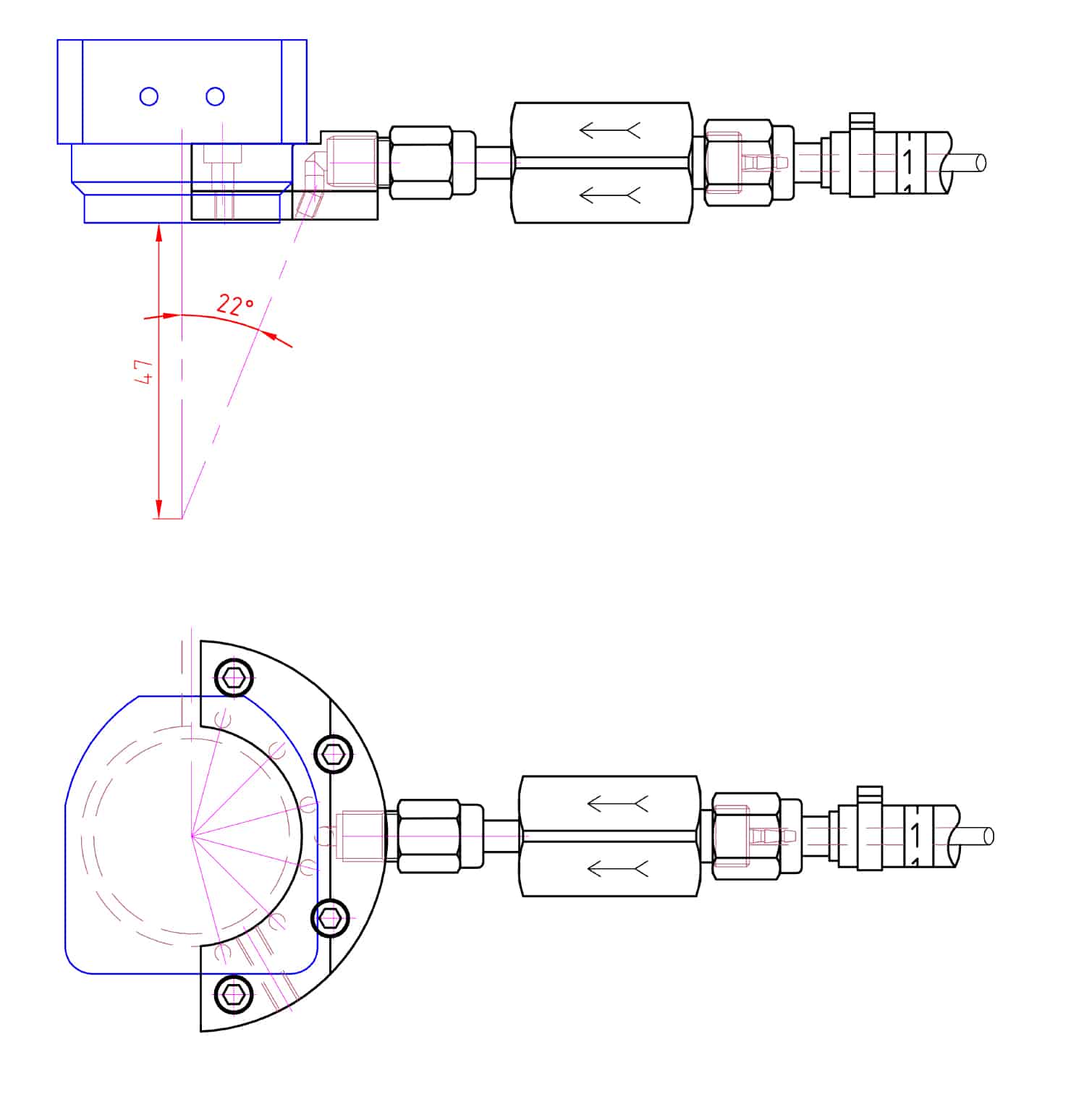

- New product, semi-annular nozzle

For best results: Quasi-dry machining

Unilube generally recommends using tools with internal cooling, where the high-performance lubricant reaches its point of application by means of internally supplied compressed air.

Challenge

This method soon comes up against its physical limits, however, when it comes to very small tools used in micro-cutting. In addition, the tool spindle used provides no room for a central supply of lubricant due to its limited dimensions. With just one lateral nozzle, although enough lubricant reaches the tool in case of high-speed micro-tools, shaded areas may arise depending on the nozzle positioning and workpiece that interrupt the application of micro-lubricant film. This can be the case especially in 5-axis machining.

Solution

In order to ensure a constant film of micro-lubrication without discontinuities, with the semi-annular nozzle the jet is split from one supply by a dual nozzle unit, in other words two “nozzle levels”, and applied from several sides to where it is needed with pinpoint accuracy.

Benefits

The finely coordinated micro-nozzles guarantee an all-round constant application of micro-lubricant film onto the tool. By varying the nozzle outlet angle, extremely different tool lengths can be reliably serviced with the innovative Unilube ltotal-loss ubrication if required.

Prospects

Originally developed for the watchmaking industry, this proven “dual nozzle principle”, adapted to customer-specific structural shapes, opens up interesting and various possible applications including the tube machining sector. Moreover, the low operating costs with oil consumption of less than 1 litre per year are surely record breaking.

Did you like this blog article? Subscribe to our newsletter and we will provide you with the latest specialist knowledge all round quasi-dry machining every month.